Hub motors are increasingly integrated into electric bicycles, scooters, and other compact electric vehicles. By placing the motor directly inside the wheel hub, they eliminate the need for chains or external gear systems, simplifying both design and maintenance. As more people seek convenient options for city commuting and leisure riding, hub motors have become a reliable and commonly used solution for electric bike users.

How Hub Motors Work

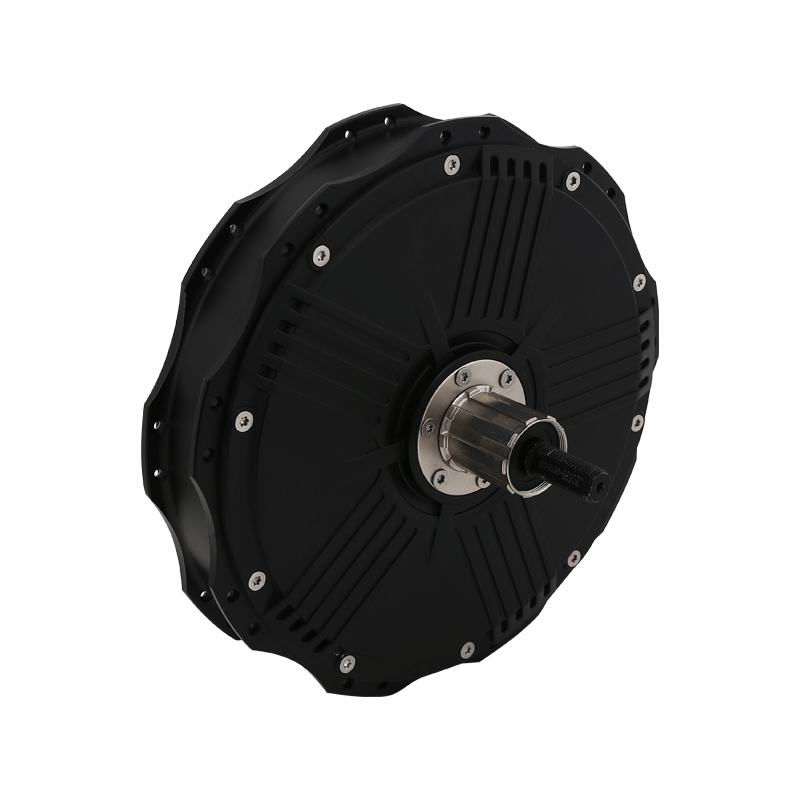

A hub motor is an electric motor integrated into the wheel itself. Unlike mid-drive systems that transfer power to the crank, hub motors deliver torque directly to the wheel. This design reduces the number of mechanical parts and allows for easier installation and maintenance.

There are two main types of hub motors:

- Geared hub motors use internal gears to increase torque. They are ideal for city commuting, offering quick acceleration and efficient energy use for stop-and-go traffic.

- Direct drive hub motors have fewer moving parts and can support regenerative braking, which recovers energy during braking. They are typically quieter and offer smoother performance on flat terrain.

Geared hub motors remain common due to their combination of lightweight design and practical performance.

Practical Benefits

One of the main advantages of hub motors is their simplicity. Without chains or belts, the bike requires less maintenance, and there are fewer exposed components to be affected by dirt or weather. The design also reduces installation time for manufacturers and makes retrofitting older bikes relatively easy.

Hub motors provide quiet, smooth operation, especially on flat roads and short trips. For city riders, the consistent performance in frequent stopping and starting is a clear benefit. They are compatible with standard wheel sizes and can be integrated into a wide variety of bicycle frames.

From a cost perspective, hub motor systems are generally more affordable than mid-drive alternatives. This lower price point makes them attractive to riders who want an electric boost without investing in high-end performance models.

Limitations to Consider

Despite their advantages, hub motors come with some trade-offs. Adding mass to the wheel assembly increases unsprung weight, which can slightly affect ride quality and handling. Hub motors usually provide less torque than mid-drive systems, making steep inclines or heavy loads more challenging. Servicing a hub motor often requires wheel removal, which can be more complex than maintaining a frame-mounted motor.

These factors make hub motors suited for flat terrain, urban commuting, and everyday riding rather than off-road or performance-focused use.

Market Context

Electric bikes with hub motors have grown in popularity due to urban mobility needs, environmental awareness, and government programs supporting low-emission transport. Their simplicity and affordability make them a practical choice for riders seeking reliable, low-maintenance solutions.

Frequently Asked Questions

1. Are hub motors better for city riding or long-distance trips?

Hub motors are ideal for city riding and short to moderate distances. They perform on flat terrain with frequent stops, though they are less suited for steep hills or extended rides.

2. Do hub motors require special maintenance?

Generally, hub motors need minimal maintenance. Repairs may require wheel removal but routine upkeep is simpler than mid-drive systems.

3. Can hub motors recover energy while braking?

Some direct drive hub motors support regenerative braking, recovering a small portion of energy during deceleration.

4. How do hub motors affect bike handling?

The additional weight in the wheel can slightly reduce maneuverability and affect ride comfort on uneven surfaces.

5. Are hub motor e-bikes cost-effective?

Yes, hub motors tend to be more affordable than mid-drive systems, offering a practical option for budget-conscious riders.

+86-13575856566

+86-13575856566

.png?imageView2/2/w/600/h/600/format/webp/q/75)

.png?imageView2/2/w/600/h/600/format/webp/q/75)

.png?imageView2/2/w/600/h/600/format/webp/q/75)

.png?imageView2/2/w/600/h/600/format/webp/q/75)

.png?imageView2/2/w/600/h/600/format/webp/q/75)