Electric two‑wheeler motors are central to the performance and efficiency of scooters, e‑bikes, and electric motorcycles. Engineers and manufacturers are focusing on innovations that improve durability, torque delivery, and energy efficiency.

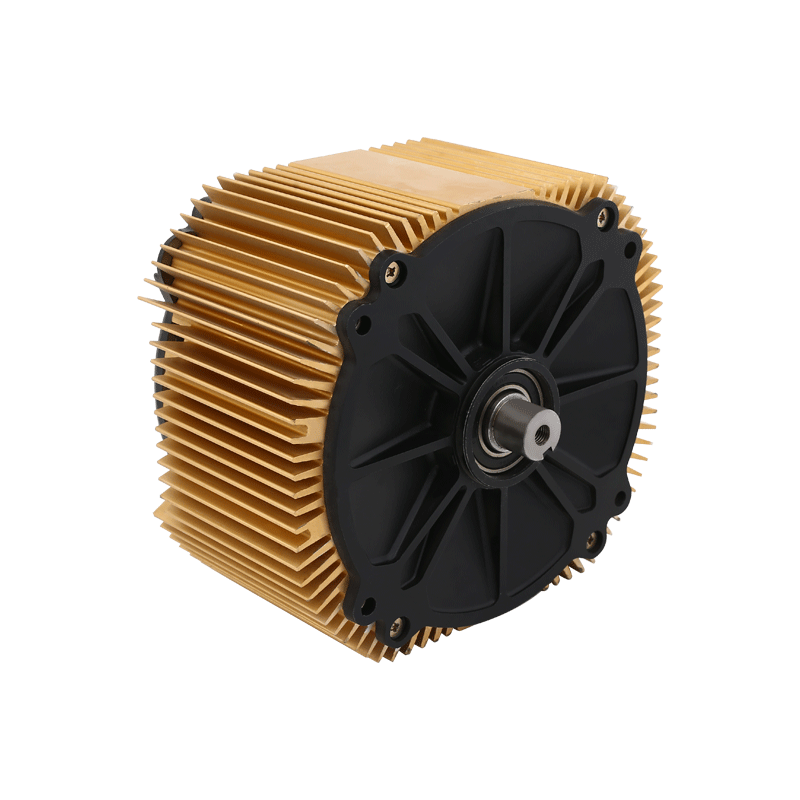

Hub Motors: Compact and Efficient

Hub motors are widely used because they integrate directly into the wheel hub, driving the wheel without additional transmission. This design simplifies assembly, reduces maintenance, and saves space, making it popular for urban e‑bikes and scooters. Hub motors are available in various power ranges, from 250W for commuter bikes to over 3000W for high‑performance electric motorcycles.

While hub motors are compact, they present challenges related to unsprung weight and thermal management. Designers address these issues by improving winding designs, incorporating high‑efficiency magnets, and optimizing the motor’s internal cooling paths. These improvements allow hub motors to provide consistent performance even in dense urban traffic or during longer rides.

Mid‑Drive Motors: Balanced Performance

Mid‑drive motors are mounted near the crankset and transmit power through the vehicle’s drivetrain. This configuration distributes weight more evenly, enhancing handling and stability. Mid‑drive motors also take advantage of the gearing system, providing higher torque and better efficiency in hilly terrain or for off‑road applications.

These motors are growing in popularity in both commuter and leisure e‑bike segments. They enable precise torque control and smoother pedal assistance, improving rider experience across different speeds and terrains. Although more complex than hub motors, mid‑drive systems offer performance advantages that justify the added cost for certain riders.

Materials Innovation: Reducing Rare‑Earth Dependence

Motor performance depends heavily on materials, particularly magnets and electrical steel. Traditional permanent magnet motors often rely on rare‑earth elements, such as neodymium, which are costly and subject to supply limitations.

Recent innovations include rare‑earth‑free motors using ferrite or alternative magnetic materials. While these motors may have slightly lower energy density, they reduce dependency on critical materials and lower production costs. Manufacturers are combining these new materials with optimized winding patterns and efficient cooling to maintain performance levels comparable to rare‑earth designs.

Data and Market Context

Hub and mid‑drive motors serve different segments. Hub motors dominate lightweight and urban applications, while mid‑drive motors are preferred for high‑torque and performance‑oriented bikes. Estimates suggest the global hub motor market could reach $12 billion by 2025, and mid‑drive motors are growing steadily in commuter and leisure markets. Advances in materials are further supporting cost-effective expansion across emerging regions.

FAQs

Q1: What is the main difference between hub and mid‑drive motors?

Hub motors are installed in the wheel and provide direct drive. Mid‑drive motors connect to the drivetrain, allowing better torque distribution and weight balance.

Q2: Which motor type is more efficient?

Efficiency depends on usage. Hub motors work well for flat urban commuting, while mid‑drive motors perform better on hills or mixed terrain due to gear leverage.

Q3: Why are rare‑earth‑free motors important?

They reduce dependence on materials like neodymium, lower costs, and improve supply chain resilience.

Q4: Do these motors need cooling?

Yes. High-power hub and mid‑drive motors use passive or active cooling to maintain efficiency and prevent overheating.

Electric two‑wheeler motors continue to evolve through design, integration, and material innovations, meeting diverse urban mobility needs while balancing performance and sustainability.

+86-13575856566

+86-13575856566

.png?imageView2/2/w/600/h/600/format/webp/q/75)

.png?imageView2/2/w/600/h/600/format/webp/q/75)

.png?imageView2/2/w/600/h/600/format/webp/q/75)

.png?imageView2/2/w/600/h/600/format/webp/q/75)

.png?imageView2/2/w/600/h/600/format/webp/q/75)